In the realm of cutting-edge technology, 3D printers have continued to evolve, and in 2023, the market will witness a range of groundbreaking yet expensive options.

3D printing is an extraordinary technology with many procedures, materials, and applications. You can take home a dependable 3D printer for a few hundred dollars and use it to create a wide range of parts and sculptures from inexpensive plastic filament.

Understanding the Top expensive of 3D Printing Technology

3D printing has transformed sectors ranging from aerospace to healthcare in recent years. These printers use additive manufacturing techniques to build complicated structures layer by layer. Several factors contribute to sophisticated 3D printers’ high prices. Innovative features, accuracy, build volume, material compatibility, and post-processing capabilities all substantially impact cost.

Many Features that boost a 3D printer’s price value:

1. The technology’s one-of-a-kindness

2. How automated are the processes?

3. The size of the capacity Quality assurance aspects

4. Exclusive software

5. Several controls and adjustments

Despite their high initial cost, 3D printers pay for themselves quickly because no other manufacturing process can produce parts with the level of complexity that these machines can. This has allowed incredible technological advancements in products like motors, rocket engines, and medical implants.

Types Of 3d Printers:

1. Digital Light Processing (DLP) is a 3D printing technology that works with photopolymers, comparable to stereolithography (SLA).

2. Electron Beam Melting (EBM) is comparable to Selective Laser Sintering (SLS) in that both print from the powder bed of a 3D printer.

3. A 3D printer that uses fused deposition modeling (FDM) or fused filament fabrication (FFF) is named for its process, which involves melting plastic filament layer by layer to construct a 3D model physically.

4. A 3D printer for hobbyists/enthusiasts or prototyping – since that is what it is used for, or its application.

5. A cartesian 3D printer moves the printer head according to the cartesian coordinate system (X, Y, and Z).

6. A thermoplastic 3D printer, uses melt-able plastic filament to print with. It may also be categorized as a multi-material/water-soluble support 3D printer because it has two extruders, which allow it to print two distinct materials, one of which may be water-soluble supports.

A Comparison of the Top Expensive 3D Printers

| Printer Model | Precision Level | Build Volume | Material Compatibility | Unique Features |

| SLM Solutions NXG Xll 600 | 10 microns | 600 x 600 x 600 mm | Various metals | Dual lasers, advanced cooling systems |

| XJet Carmel 1400C | 6 microns | 1400 x 1400 x 1800 mm | Metal and ceramic materials | Nano-Particle Jetting™ technology, proprietary software |

| EPlus3D EP-M1250 | 15 microns | 1250 x 1250 x 1250 mm | Industrial-grade polymers | Advanced slicing algorithms, high-speed printing capabilities |

This table summarizes the key specifications and unique features of each printer, aiding in a quick comparison for those seeking specific functionalities or capabilities.

EP-M1250:

EPlus3D designs and manufactures large metal 3D printers for the country’s demanding industrial industry. Models from the firm are used in aircraft, automotive, electronics, and tooling to create not just large parts, such as molds for heavy industries, but also mass-produced parts.

The EP-M1250 metal 3D Printer is the company’s biggest, with a build volume of 1,258 1,258 x 1,350 mm and a pace of 240 cm3 per hour. It employs metal powder and nine lasers to make 99.9% dense metal pieces in a variety of materials.

Carmel 1400C:

A one-of-a-kind ceramic 3D printing technique at a premium price. Nano-Particle Jetting (NPJ) technology allows for the creation of metal and ceramic components with exceptional detail, polish, and precision. The extensive automation in the printer itself makes it easy to operate, not only the technology and exclusive materials that make this printer a considerable investment.

The Carmel 1400C, with its 1,400 cm2 build tray, is one of the industry’s biggest and allows for the simultaneous creation of several ceramic pieces.

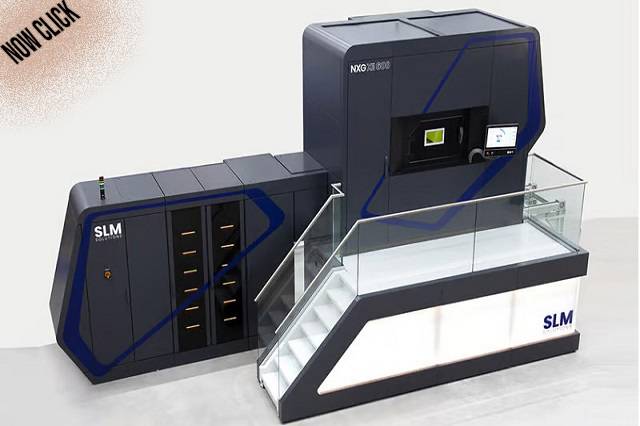

NXG Xll 600:

SLM Solutions of Germany is a leader in metal 3D printing with a wide range of printers, but their NXG 600 is billed as a revolution in industrial production. The NXG XII 600 is intended for high-volume serial manufacturing and has an industry-first 12 lasers each rated at 1,000 Watts. The lasers provide unprecedented speed and throughput in a single machine.

The NXG 600 is more than just a laser; it has all of the bells and whistles that SLM Solutions’ manufacturing clients have come to expect over the years, such as an automated build start, a laser focus function, and a closed powder system, among other advancements.

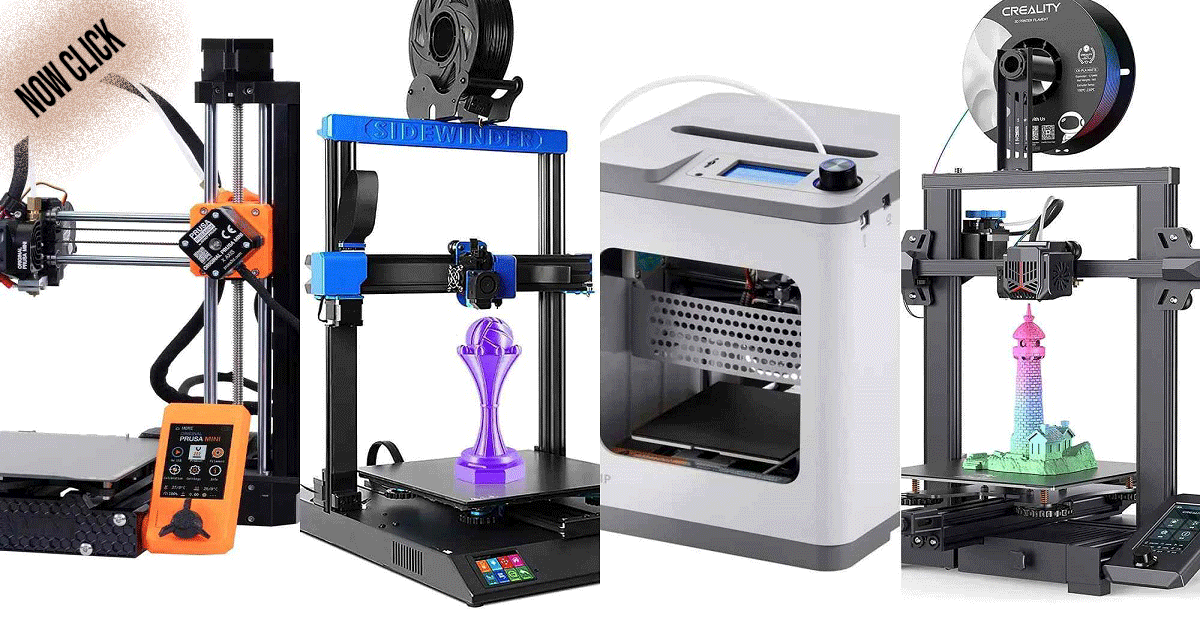

Comparing the performance between Affordable and Expensive 3D Printers:

The volume of Construction:

In general, cheaper 3D printers have lower build volumes, but more costly printers have greater build volumes that can handle larger items.

Resolution of the Layers:

Expensive printers have better layer resolution, resulting in smoother, more detailed prints, whereas low-cost printers have lower layer resolution, resulting in noticeable layer lines and less detail.

Accuracy:

Expensive printers are often more exact, resulting in better accuracy and fewer mistakes, whereas low-cost printers may be less precise and create lower-quality prints.

Cost:

Cheap printers, as the name suggests, are less expensive than their more expensive counterparts. They may, however, have limits in terms of printing capability and quality. Expensive printers might be an expensive purchase, but they frequently provide more features, higher quality, and greater adaptability.

Cheap 3D printers are less expensive and more suited for novices and enthusiasts, as well as basic and low-volume printing jobs. Expensive 3D printers, on the other hand, provide superior quality and precision, a wider selection of materials and printing capabilities, and are excellent for high-volume and professional printing tasks. When selecting, it is critical to carefully analyze these variables and select the finest 3D printer for your demands and budget.

Conclusion:

In conclusion, the evolution of 3D printing technology has brought forth remarkable advancements. While the cost may be a barrier, these high-end printers offer unparalleled precision, versatility, and capabilities, catering to industries that demand top-tier performance.